Filtermist Systems has been on a mission to educate global manufacturers about the potential harm that can be caused by exposure to airborne oil mist particles ever since it first started manufacturing in 1969.

Despite the Health and Safety Executive running inspection campaigns focussing on control measures for metalworking fluids and welding fume for the past few years, the use of LEV systems on all CNC machines is still not where it needs to be, as Craig Woodward, Filtermist’s Divisional Sales Director for oil mist, explains; “My team visits manufacturers throughout the UK every day of the week, and whilst many of them do recognise how important it is to protect their employees from exposure to airborne particles, there is still a long way to go.

“Many employers have LEV on some CNC machines, but not all and in cases like this, a HSE Inspector would mark the employer as not having effective control measures in place. Anecdotally, there can be many reasons why this is the case – some employers think certain machines do not emit enough particulate to warrant installing LEV, some think the risk from exposure to metalworking fluid is low, some don’t realise the extent of their obligations under COSHH, and some choose to turn a blind eye to save money.

“Human behaviour can be influenced by so many factors it can be difficult to establish exactly why someone chooses not to protect themselves or their colleagues from potential risk. Usually, it’s not a case of willingly putting employees at risk, it’s just that the risk is underestimated. In an ideal world, we would like the use of LEV on CNC machines to become as normal as fastening a seatbelt when you get in a car, or putting a helmet on before welding.”

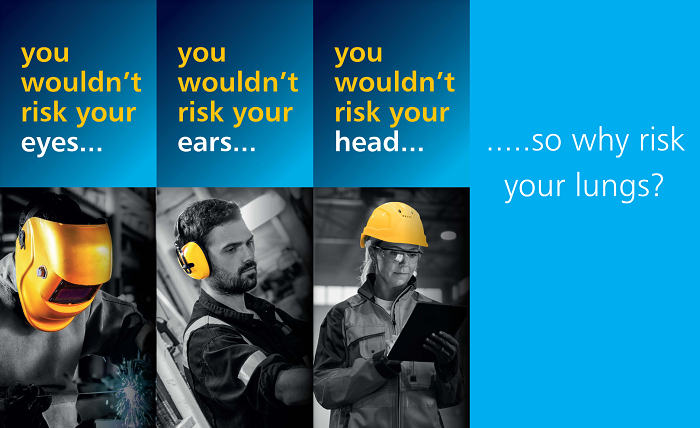

PPE is widely used in all manufacturing businesses, but should actually be the last resort if the hierarchy of controls is used properly. However, because the risk to people’s lungs associated with exposure to airborne oil mist, dust and fume particles is far less immediate than arc eye or a blow to the head, it can easily be overlooked. And because there aren’t many accounts in the public domain from people who have been affected by exposure to metalworking fluids, it can be easy for employers to believe the risk is being overstated.

Filtermist recently published an article entitled ‘Oil mist exposure – HSE hype or a real health hazard?’ to try and help to dispel the myth that the risks have been exaggerated. And anyone who has listened to ‘Phil the Welder’ talk to the HSE about his experience of exposure to welding fume will know just how debilitating the long-term effects of occupational asthma can be.

If you’d like to make sure that your control measures for exposure to oil mist particles, dust or fume are working effectively, give our team a call on 01952 290500 or email sales@filtermist.com and we’ll undertake a free LEV site survey to put your mind at ease.