Health and Safety professionals use a variety of processes, frameworks and procedures to ensure all risks within their organisations are minimised. We spoke to Filtermist’s QSHE (Quality Safety Health and Environment) Manager, Gail Lees, to find out more about the Hierarchy of Controls (HoC) – what it is and why it’s used, what it means for employers and how Filtermist’s products and services fit within the hierarchy.

Filtermist: Gail, please tell us a bit more about the Hierarchy of Controls

GL: It is widely accepted that the globally recognised Hierarchy of Controls framework was introduced in the 1950s and has been used to help ensure all identified risks to health and safety are managed as effectively as possible for more than 70 years.

In Great Britain, the HSE recognises that not all risks can be removed entirely, but employers are required to reduce them to ALARP ‘as low as reasonably practicable’.

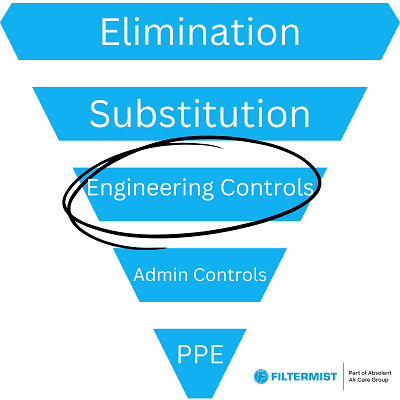

The Hierarchy of Controls framework consists of five key areas, in diminishing order of importance:

- Elimination – this is the most effective control. If possible, risk should be ‘designed out’ completely

- Substitution – replace the materials, machinery or process with less risky alternatives

- Engineering Controls – protect workers by removing hazardous conditions or by placing a barrier between the worker and the potential hazard. Examples include safety equipment such as machine guards or local exhaust ventilation (LEV) to capture and remove potentially hazardous airborne particles

- Administrative Controls – amend working practices. This could include changing the shift length, reorganising workers, providing additional training, using signage to remind employees about key points, and undertaking and recording regular checks to equipment.

- PPE (personal protective equipment) - should be used as a last resort. This is because PPE only reduces risk for the individual wearer and it can make some tasks more cumbersome, therefore making it more likely that the employee may try to avoid using it

Filtermist: Why does the HSE and other bodies responsible for overseeing health and safety around the world use the HoC?

GL: Like all frameworks, the HoC helps employers to think about potential risk from the widest viewpoint possible to ensure possible solutions are not overlooked. Employers need to ask themselves if the risk can be eliminated completely as a starting point, but if it can’t, what can be done to reduce the risk to ALARP?

Filtermist: Why is it important that employers use this framework?

GL: There are two over-riding reasons for this:

- All employers have a moral responsibility to employees to make sure their working environment is as safe as possible, and all potential risks have been identified and measures implemented to minimise risk as much as possible

- Under the Health and Safety at Work Act (HASAWA) etc 1974, all employers have a legal duty to keep their employees safe in the workplace. In the event of a visit from HSE, employers may be asked to share risk assessments detailing what control measures have been implemented and why. Employers relying solely on PPE when alternative measures could have been used may find themselves subject to an enforcement notice or notification of contravention if the HSE inspector decides the employer is not complying with any of the Regulations contained within the HASAWA 1974.

Filtermist: How do products and services from Filtermist fit within the HoC?

GL: LEV is classed as an Engineering Control. Filtermist has manufactured and supplied LEV systems since 1969. The company originally manufactured its own brand of oil mist filters which are used on CNC machines that use coolant to keep metal components cool during a variety of machining applications. It then became the distributor for premium filters for oil mist and oil smoke from Absolent AB in 2010, and in 2017 acquired the Dustcheck brand of process and venting filters, and wet and dry dust collectors. Dustcheck industrial dust collectors are used in a wide range of industries including food production, pharmaceutical, agriculture and construction materials.

The HSE (Health and Safety Executive) has an excellent film on its YouTube channel explaining what LEV is and how it works: https://youtu.be/Ky8y2jDk6i8

Filtermist: Can Engineering Controls be fitted retrospectively?

GL: They can. All employers should regularly review their risk assessments (RA) to ensure control measures remain effective. If a process or working practice has changed since the original RA, it may be decided that Engineering Controls need to be implemented.

Filtermist: And what about ongoing support? Once an employer has fitted LEV, do they need to do anything else?

GL: Yes they do! COSHH (Control of Substances Hazardous to Health) Regulations 2022 require all LEV systems to be thoroughly examined and tested by a competent person at least once every 14 months depending on the application. Employers are also required to keep LEV systems in good working order. Filtermist has teams of engineers that service and test LEV systems of all makes and models throughout the UK.

If you would like to discuss how Filtermist can specify, design, install and maintain the best LEV solution for your specific requirements, please call us on 01952 290500, email sales@filtermist.com or fill in our contact form and a member of our team will be in touch shortly.